Thorne & Derrick - GRP Cable Support Systems | Features & Benefits

Posted on 25 November 2022

GRP Cable Support Systems

Thorne & Derrick together with Mita® can offer an extensive range of GRP cable support solutions that are suitable for any kind of application. As a leading manufacturer of corrosion resistant industrial cable support products, Mita® hereby presents all you need to carry and support each and every kind of electric cable, data, instrumentation, computer or power circuit without any doubt.

Their GRP offer includes a complete industrial cable support systems and trough range specifically designed for harsh and corrosive environments. Whether you are specifying a range of equipment for a major project or buying a selection of components for a simple maintenance installation, their range is unequalled.

What is GRP?

GRP is a composite material formed if glass rovings/shavings together with resin fillers and additives. GRP is the abbreviation of Glass Reinforced Polymer, meaning it is a man-made resin based material which makes it a polymer, reinforced with glass. There are also different acronyms used by different manufacturers, such as FRP and GFRP, however, they all refer to the same type of composite.

The mechanical properties of GRP can vary widely depending on the matrix fibre combination, fillers, veils, reinforcement design, and manufacturing methods.

These properties allow an initial comparison of different types of composites as well as providing a benchmark against which to measure the success of the specific recycling process in achieving acceptable material properties.

How is GRP Manufactured?

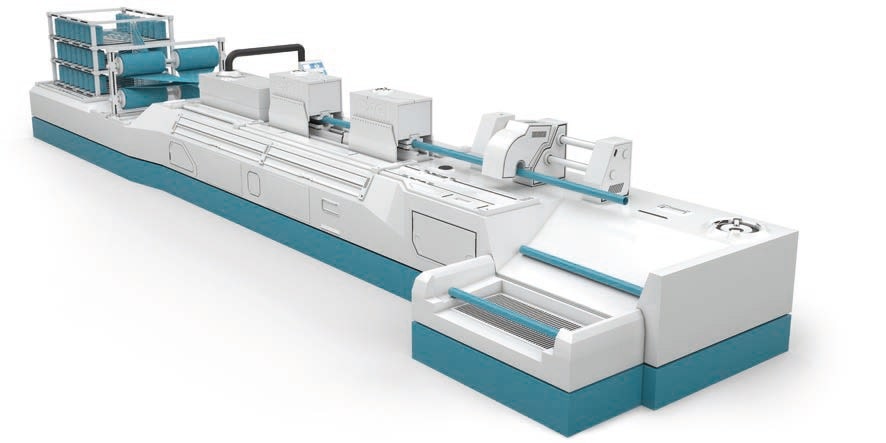

GRP is manufactured through a process called pultrusion.

Above you see the glass rovings going into the resin bath, then mats are placed on to these to create the profile first and goes into the die which shapes and cures it in the form of a ladder or tray, and at the end of the line it is cut to the required length.

Pultruded Technology is used whenever the benefits of whole life cost are appreciated and although the process was originally developed in the USA around 50 years ago, low levels of technology have traditionally meant high costs and therefore applications suited mainly to the extreme longevity of the material.

Pultruded Composites consist of four or five main elements:

1) Glass rovings (strands) and mats -approx. 50% by weight

2) Resin – usually Polyester

3) Filler – usually Calcium Carbonate

4) UV Veil and UV additives

5) Fire Retardants as required

Pultruded composites remain largely impervious to corrosion regardless of application. The GRP pultrusion process uses a combination of unidirectional and cross strand glass mat which is resin impregnated and pulled through a hot die to produce a very solid, structurally sound profile.

Pultrusion process gives outstanding structural strength when compared to other composite processing techniques.

GRP Cable Support systems

Production Methods

There are 2 common production methods for GRP cable support systems, which are moulding and lamination (though pultrusion) and do not produce the same results.

Compression Moulding:

Light / Medium Duty

1.Enough structural strength for light and medium duty applications (Low/medium load carrying )

2.Glass content is around 20-25%

3.High filler content

4.Orthothalic resin or Isopthalic resin which might end up having a low fire retardancy

5.Good for indoor applications, its manufacturing results in nice bends and better shape

Lamination through Pultrusion:

Heavy duty

1.High structural strength for heavy duty applications (high load carrying)2.Glass content is around 40-55%

3.Low filler content

4.Isopthalic polyester resin which has a good corrosion/fire performance, and Acrylic resin resulting in better corrosion, fire performance and low smoke/fumes

5.Good for indoor and outdoor applications thanks to the UV surface veil applied during the lamination

The main 2 methods that we come across in GRP cable support manufacturing is pultrusion and moulded manufacturing.

Cable Trough Resin Types

MITA offers 4 main resin types to accommodate the requirements of various industrial applications which can be in chemically aggressive, demanding heated environments.

|

POLYESTER Type 2 | Referencing Convention: Ending with PY2 This type of polyester is for general applications, is resistant to corrosion suitable in industries using heavy chemical and caustic materials, and resistant to UV light by nature. |

| POLYESTER Type 1 | Referencing Convention: Ending with PY1 This type of polyester has better fire retardance which makes it suitable for railway, trackside and any other application requiring UL94 compliance and 5VA classification. |

|

| POLYESTER Type 1 Carbon Loaded | Referencing Convention: Ending with PY1C This type of polyester has anti-static properties as it contains carbon powder. It, therefore, requires grounding. It is for on-shore and off-shore oil and gas applications which are classified as explosive environment. |

|

| MODIFIED ACRYLIC | Referencing Convention: Ending with MX This type of polyester has anti-static properties as it contains carbon powder. It, therefore, requires grounding. It is for on-shore and off-shore oil and gas applications which are classified as explosive environment. |

Cable Trough Approvals

| Materials | Standards |

| PY2 | BS 476 Part 7 |

| BS EN 60695-2-12:2001 | |

| PY1 | UL 94 – V0 |

| UL 94 – 5VA | |

| BS EN 60695-2-12:2001 | |

| PY1C | BS476 Part 7 |

| UL94 – V0 | |

| UL94 – 5VA | |

| NES713 | |

| BS60079-0 | |

| BS EN 60695-2-12:2001 | |

| MX | BS 476 Part 7 |

| BS 476 Part 6 | |

| NES 713 | |

| BS 6853 – D8.3 | |

| BS 6853 –D8.4 Cat 1B | |

| BS 6853 – Annex B2 | |

| BS EN ISO 4589-2 | |

| BS EN iSO 4589-3 | |

| UL 94 V0 | |

| UL 94 5VA | |

| BS EN ISO 4589-2 | |

| BS EN ISO 4589-3 | |

| BS EN 60695-2-12:2001 |

| References | |

| Wibe full reference | Wibe quick reference |

| Polyester Class 2 | PY2 |

| Polyester Class 1 | PY1 |

| Polyester Class 1 Anti Static | PY1C |

| Acrylic Class 0+ | MX |

GRP Cable Support Solutions

Features & Benefits

| Features | Benefits |

| Light weight Density and weight are significantly lower than steel (70% lighter than steel) with reduced handling requirements. Lightweight in design. |

Health & safety Reduced risk of staff injuries due to its lightweight, easy to cut, no hot works requirement, no deburring and no sharp edges. |

| Compression strength Despite its lower weight, tension, flexure and compression strength of GRP is almost 20 times that of steel with much greater safety factors. It does not deform permanently under high loads. Slow heat transfer allows for even stronger mechanical resistance. |

Low installation & transport costs Typically between 30-40% less than steels with easier cutting, drilling and no deburring, painting or earthing. Transportation costs are more economical and the ease of installation ensures that GRP is the more cost effective solution. |

| Slow heat transfer & resistant to electromagnetic pulses It is effective at temperatures between -140oC to +120oC. Resistant to electromagnetic pulses and transfers heat more slowly than steel. Composite materials are excellent insulators having a thermal conductivity 1/60 of a steel product, and do not require earthing. |

Long life & low maintenance Composites are corrosion resistant and maintenance free. Our GRP products are designed and manufactured to withstand a majority of chemicals & extreme weather – without requiring further maintenance. No rusting, even when exposed to salt spray, H25, acid build up from exhaust gases or brake dust. |

| Zero halogen, UV & corrosion resistance GRP cable support solution is resistant to UV and corrosion, and is zero halogen. It is also available in low smoke classified material. |

Fire performance GRP is zero halogen. It has low heat and electrical conductivity, and is available in self extinguishing and low smoke material. |

| Offer & design Available in 3m and 6m lengths. Full range of pre-manufactured bends, jointing bays and transitions available for fast installation. Dedicated design facility to support bespoke solutions. |

Installations & modifications are simpler Mita GRP solutions offer a far easier installation, without the need for painting, earth bonding or special tools. Supplying 6m or 3m lengths reduces amount of couplers required. |

MITA, Schneider Electric + Wibe Group

In 1988, Mita Holdings Ltd was born. In a short while, the company became a leading manufacturer of corrosion resistant industrial cable support products in the UK. In 2005, the company was acquired by Schneider Electric under the name of Mita (UK) Ltd. Mita name continued as a range name under the Schneider Electric brand. Finally, in 2021 the cable support division is acquired by the Swedish group, Storskogen, and is reborn as a stand alone company, Wibe Group.

MitaR is back as a leading brand in GRP cable support solutions. MITA brand is now powered by Wibe Group.

MITA have been supporting customers through their technical journey on choosing the correct product, manufactured from GRP, in cable support applications for almost five decades. MITA are now fully separated operationally from Schneider Electric. They now have a stand alone presence in the UK market with their “Made in UK” products which are fully compliant to the related cable management standards.

MITA are marker-leaders in the manufacture of GRP non-metallic troughing, GRP cable ladders, CABSYS cable trays, ducts, cable support channels and Fibastrut as the brand continues to lead the industry towards a sustainable future for a wide range of low (LV), medium (MV) and high voltage (HV) cable installation applications.